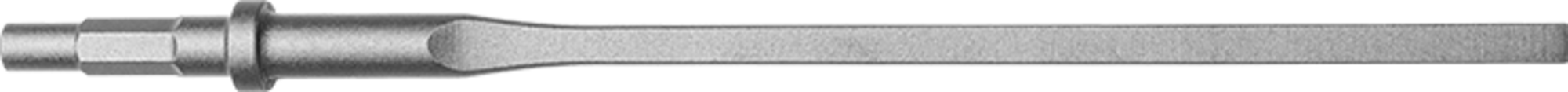

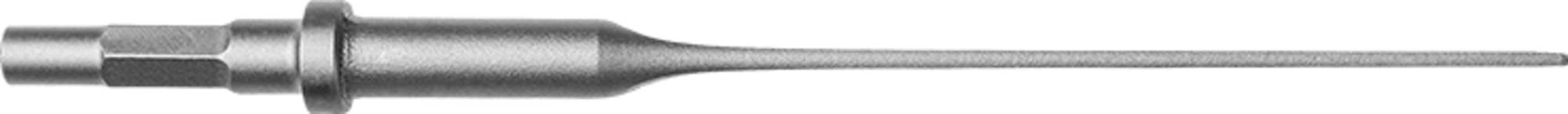

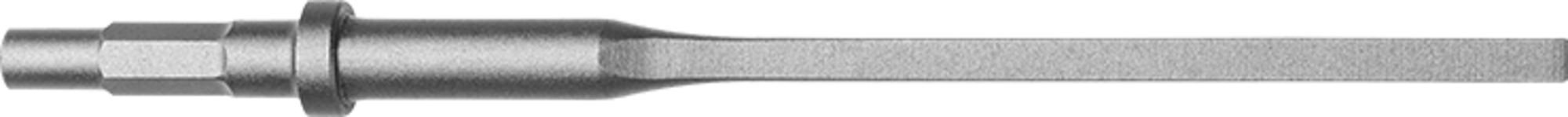

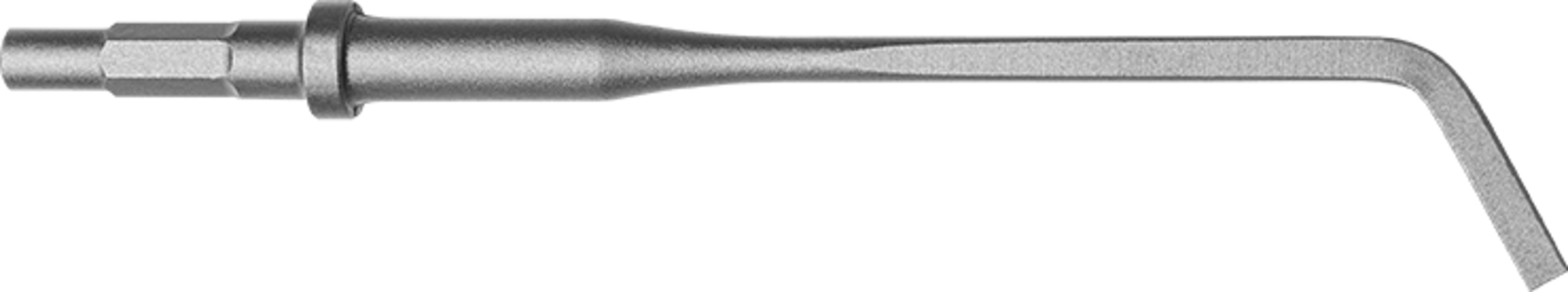

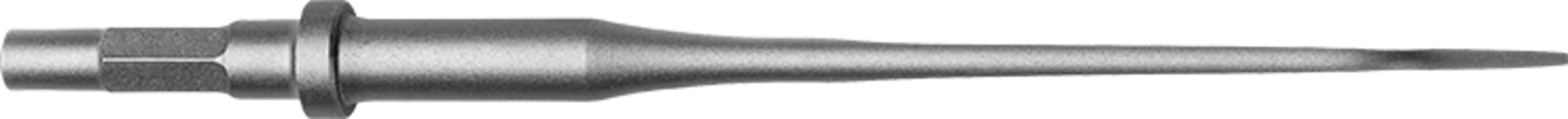

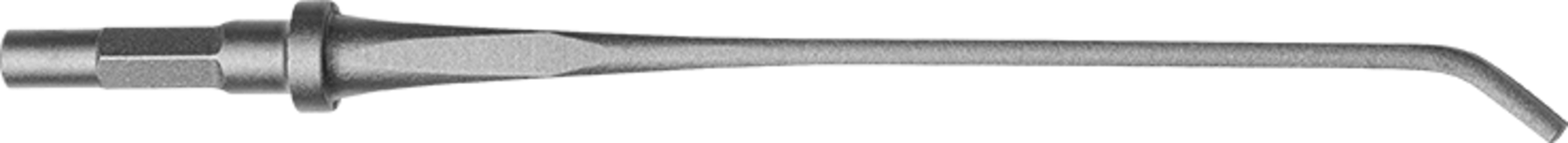

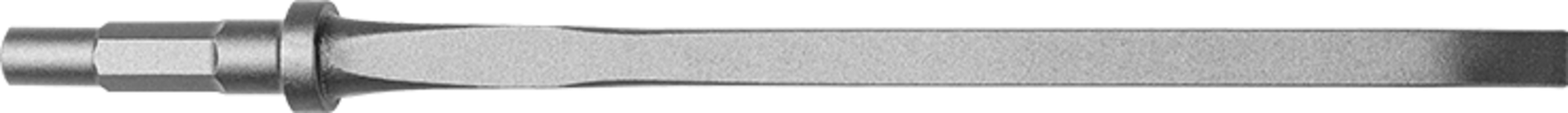

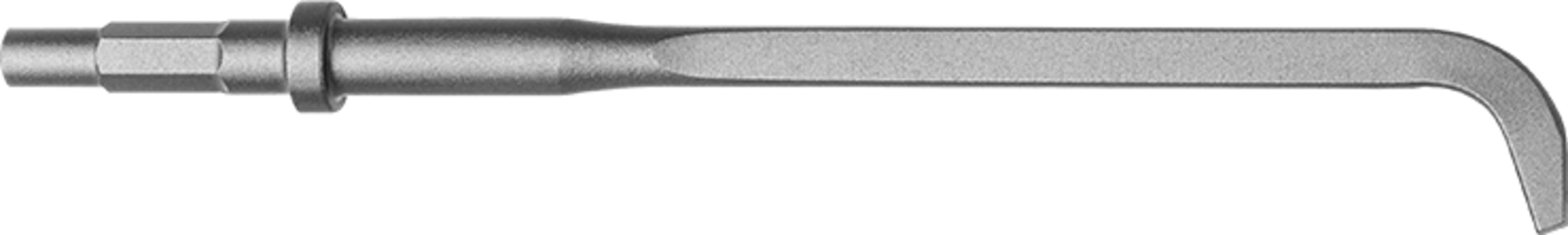

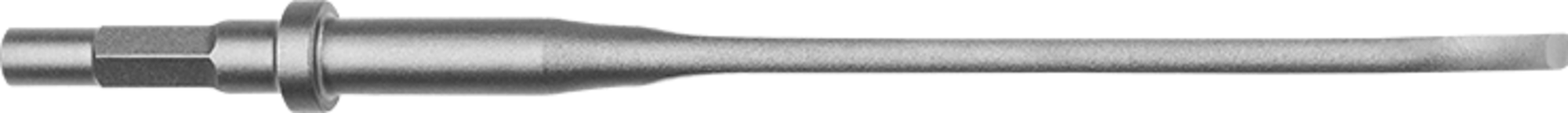

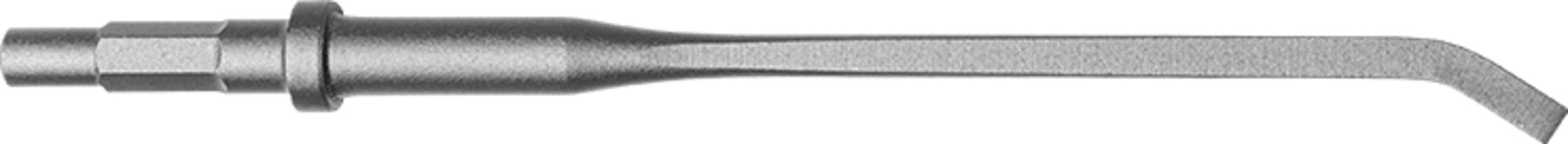

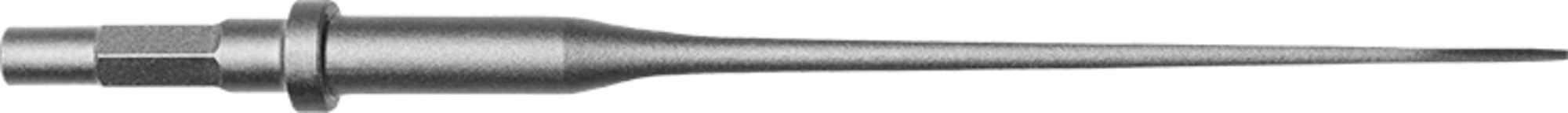

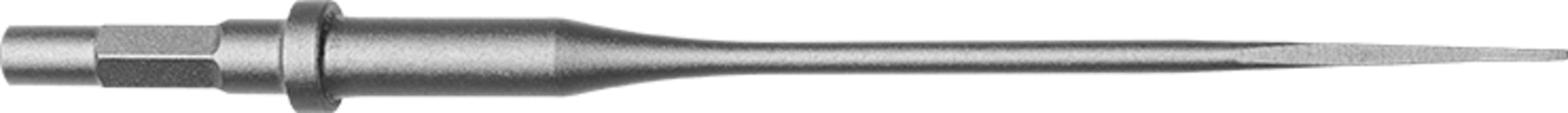

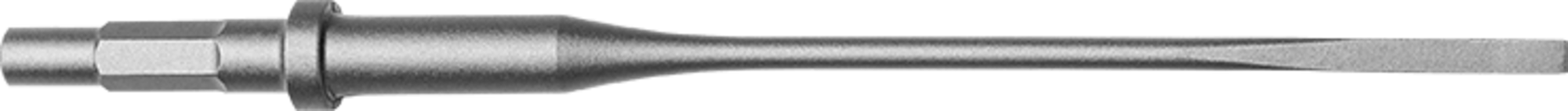

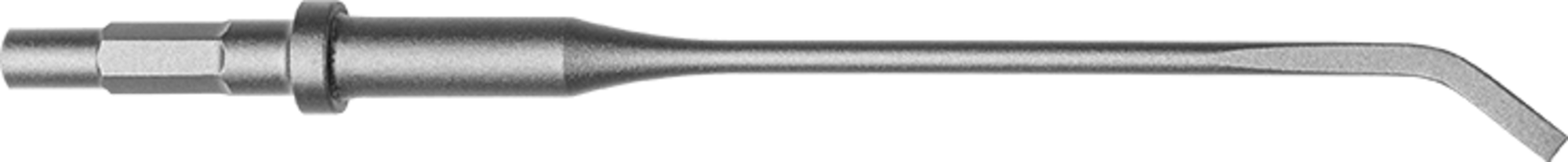

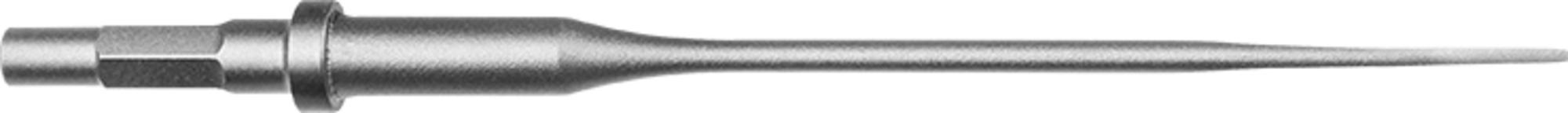

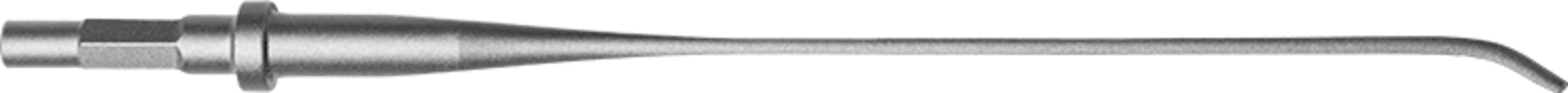

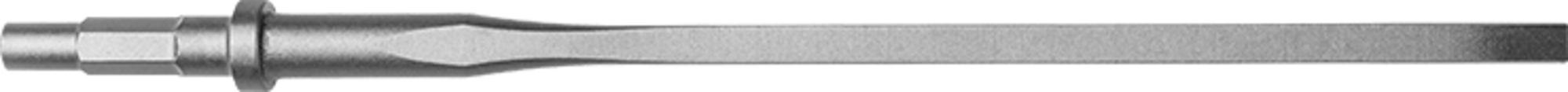

Fettling tools

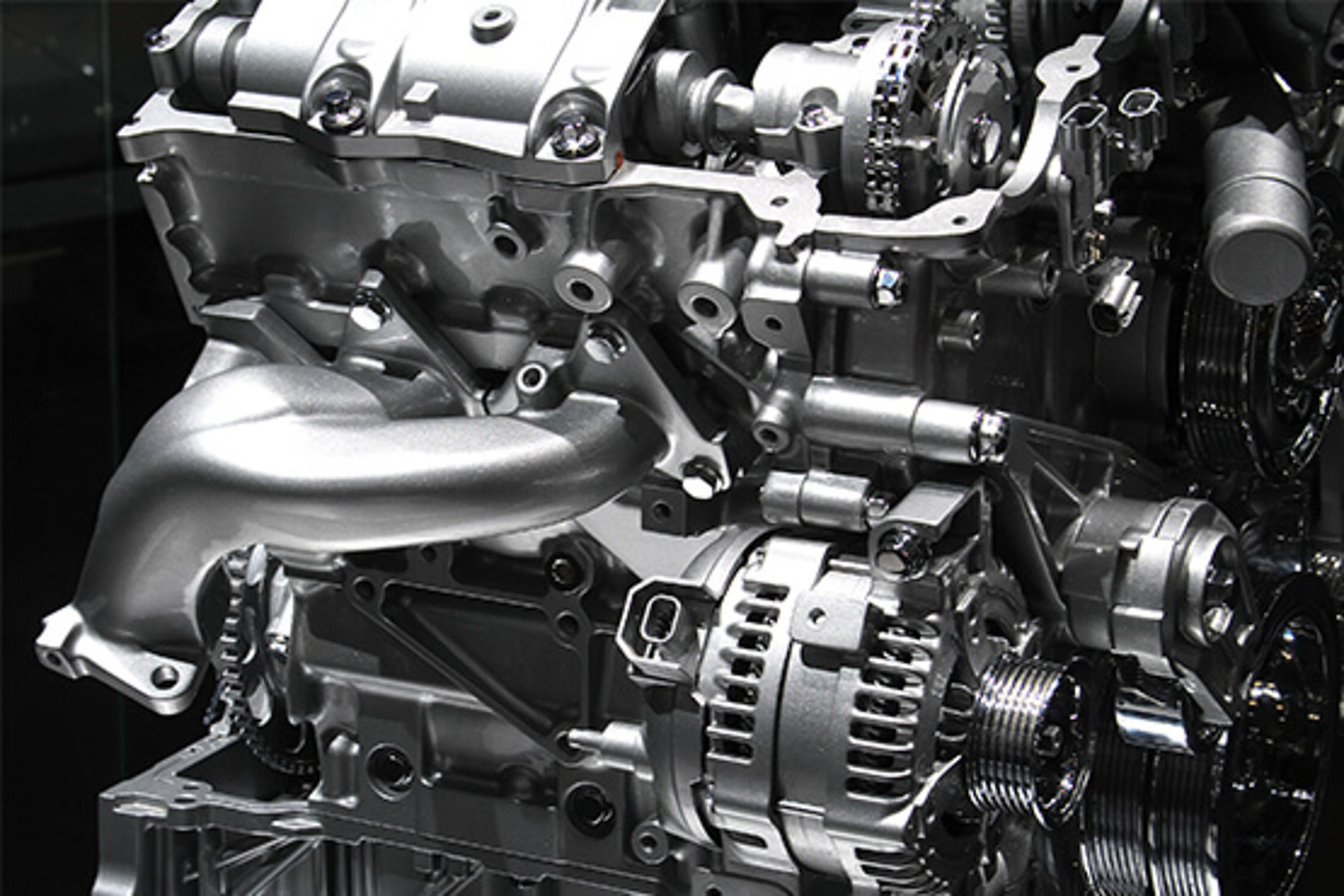

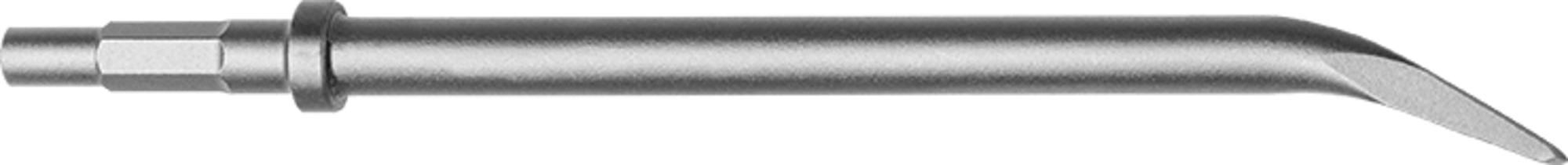

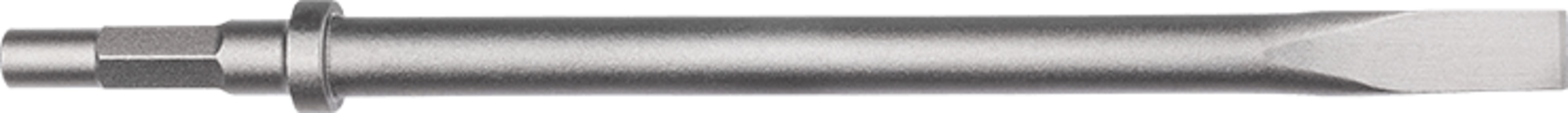

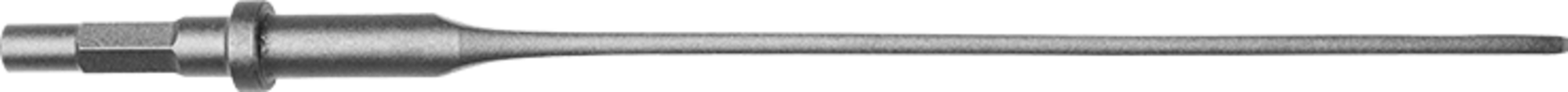

Cleaning tools by SOLIDA are used in foundries for the manual processing of cast parts. Even in modern foundry technology, cast post-treatment is still performed mechanically and by hand in many areas. The SOLIDA fettling tools are made from a special steel and are developed for pneumatic hammers, they fit precisely into the hammer chuck and deliver optimal energy transfer with incredible stability.

Use in all areas of cast processing

Following the demoulding and solidification of the most various metals and alloys in mould-casting, the post-processing of the cast parts is performed. During post-processing, rough-casting and finishing, the most diverse range of fettling tools such as hooks, spikes and chisels, including bent or angled tools, along with cleaning chisels, are used to give the workpiece the perfect appearance. This includes both common special tools, as well as custom-made special tools that are manufactured for the processing of series-produced cast parts.