Foundries - where metal reaches peak performance.

When cast parts are produced from molten metal, things get hot. Once the liquid metal solidifies in the mould, de-moulding is performed and a "one-off piece" is produced every time, which will require post-processing with varying levels of customisation - even when dealing with series production with excellent mould design, an easily cleaned/fettled construction and a perfectly controlled casting process.

Cast parts are used in the most varied sectors, such as vehicle construction, machine construction, aviation, the construction industry, art, electronics, electrical engineering, architecture, shipbuilding, rail transport and aerospace. Depending on the form and material, e.g. cast iron, aluminium, bronze, cast steel, malleable cast iron or copper, the cleaning of castings must meet the most varied requirements.

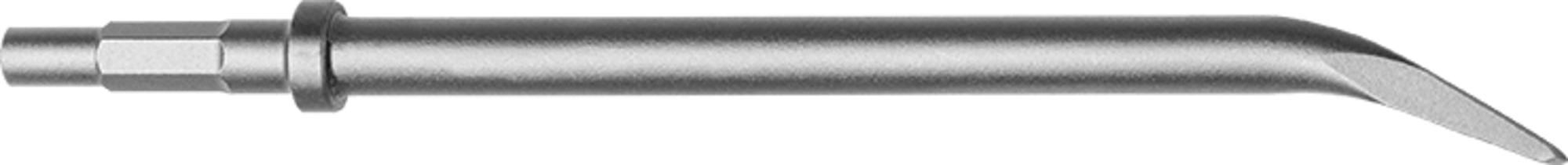

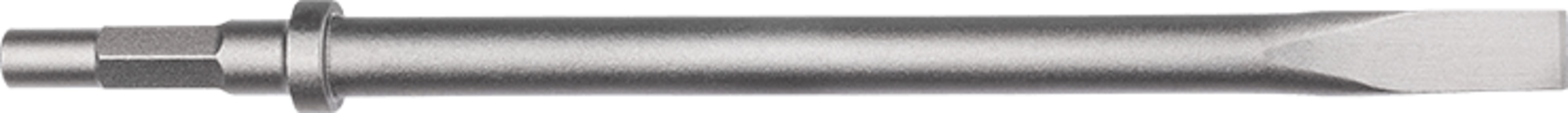

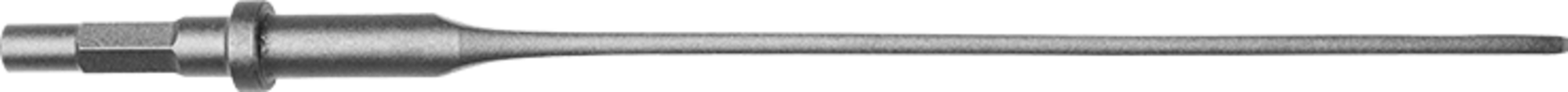

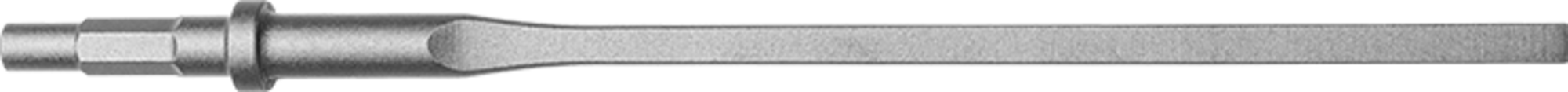

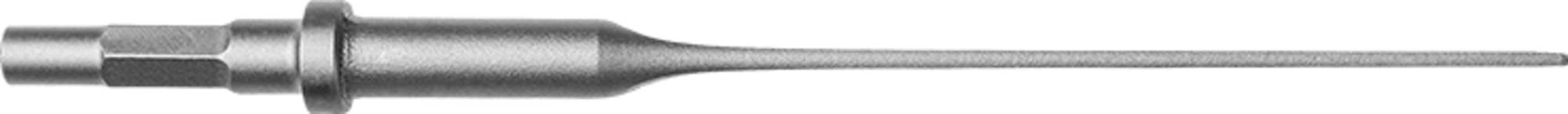

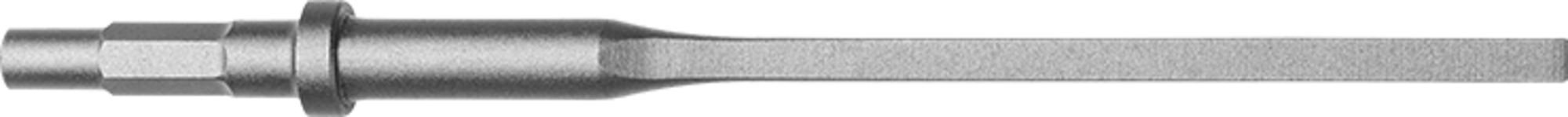

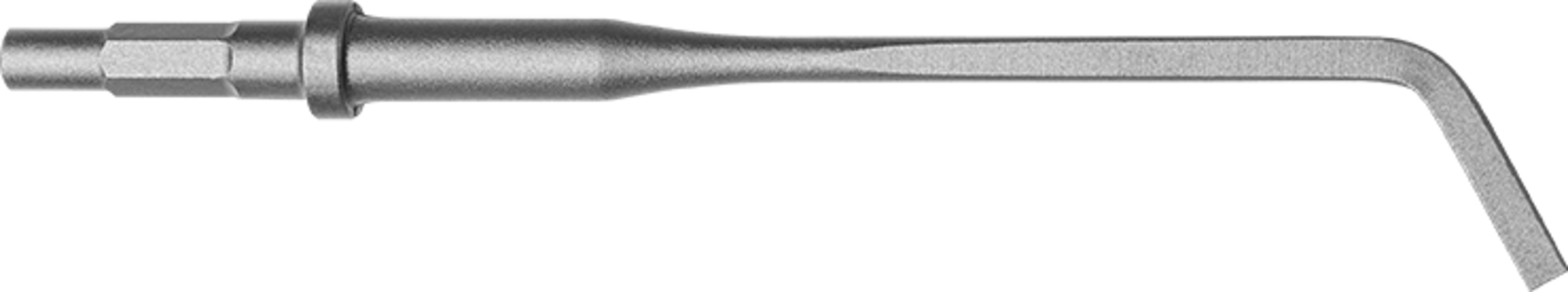

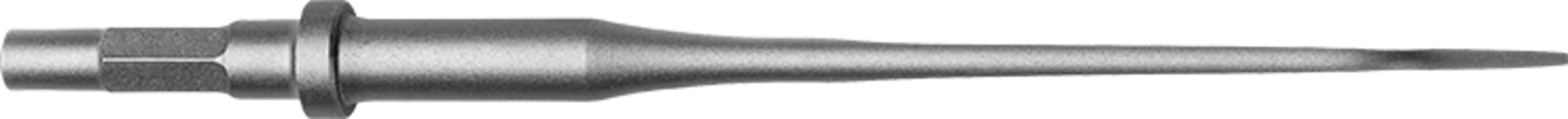

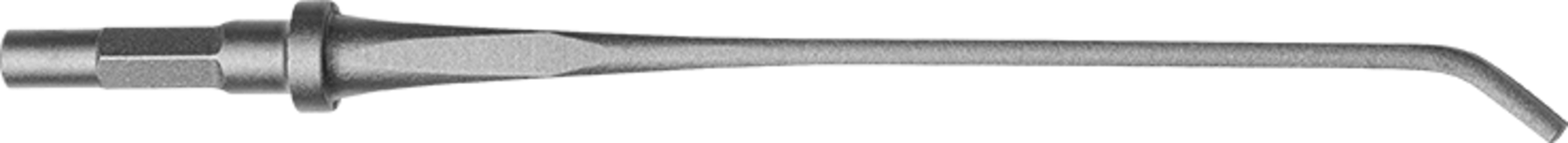

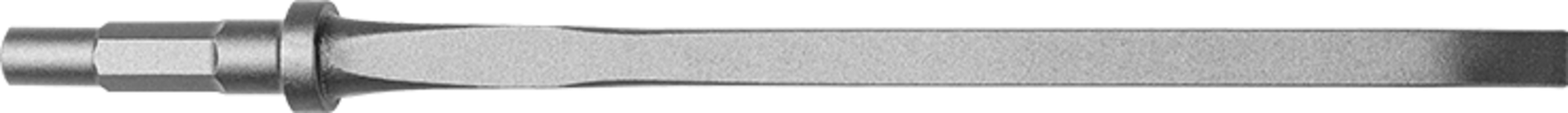

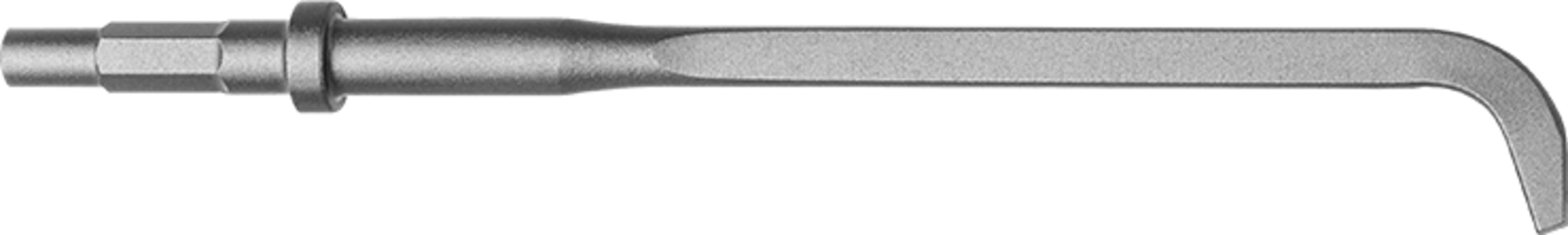

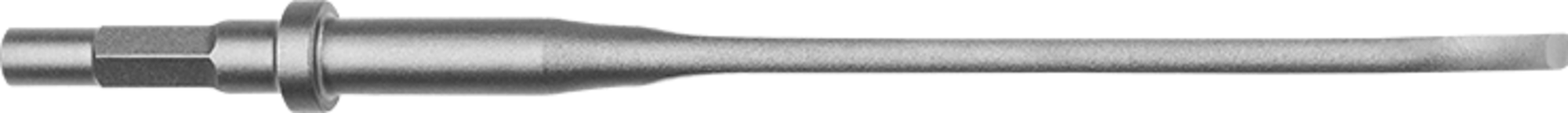

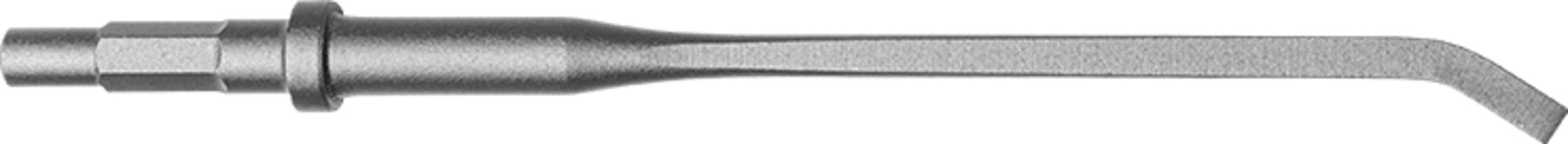

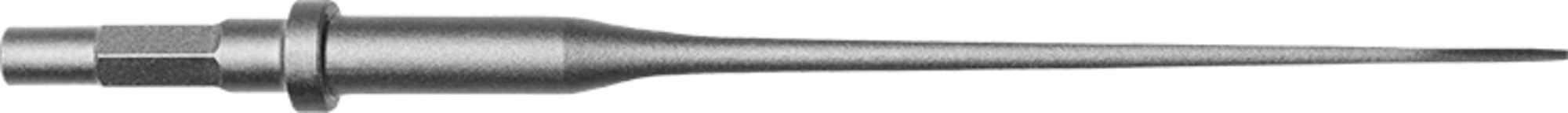

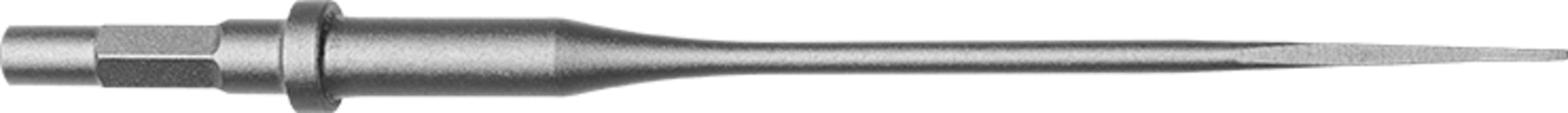

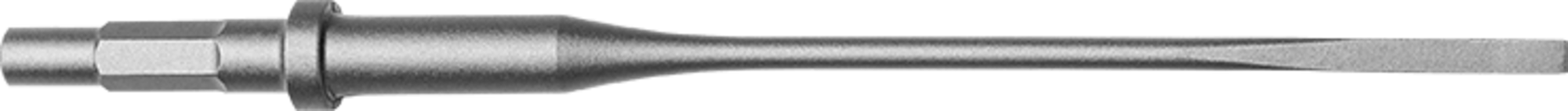

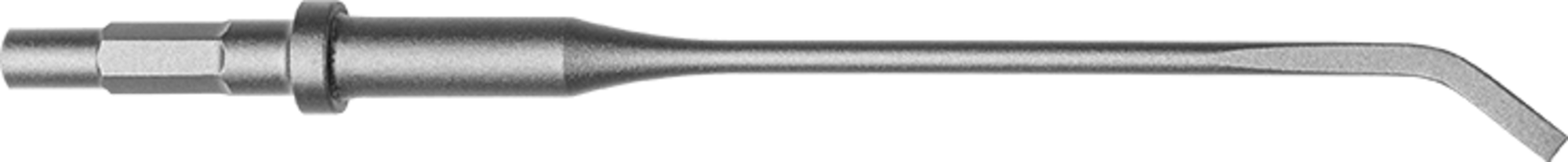

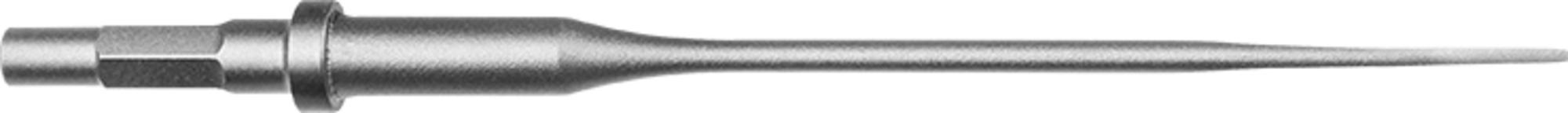

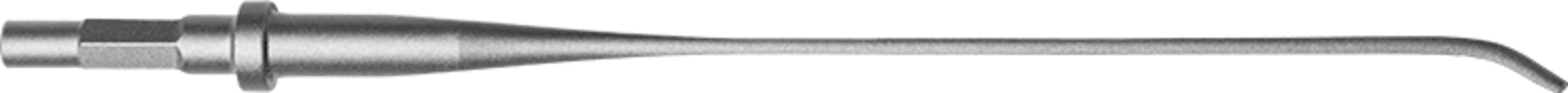

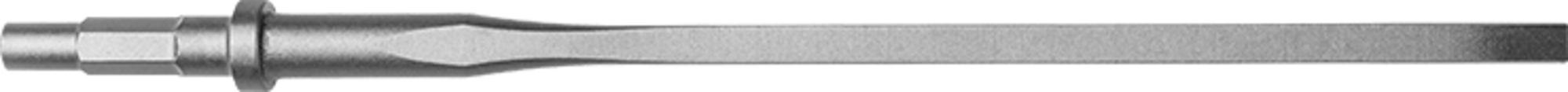

In a process involving hard - for the most part manual - work, which accounts for a large proportion of the total cost of operating a foundry, the raw cast parts are cleaned. Monitored by means of the reporting of the lead times at the production lines, it is here that SOLIDA fettling tools prove their exceptional long life and high quality. They are made from a particular special material, significantly increase tool life, measurably reduce set-up times and thus lower the costs of manual post-processing for engine blocks, bells, turbine blades, pumps, gear units, propellers, crankshafts and crank casings, cylinder heads, synthetic castings and much more.

We manufacture according to your wishes!

Please contact us and tell us your requirements and quantities.

We would be glad to advise you.

Please call us on

T +49 2191 3715-0

or e-mail to

info@solida-werk.de